Products

Contact Information

Organic Heat Carrier Marine Boiler

Product Overview:

Category:

key word: Manufacture of heat carrier boiler | steam boiler

Organic Heat Carrier Marine Boiler

Introduction

The oi-burning hot oil furnace takes fuel oil (heavy oil and light oil) as fuel and takes heat transfer oil as the heat carrier to transfer heatenergy to heat consuming device by means of high temperature hot oil circulation pump with forced liquid-phase closed-loop circulation.After heat exchange heat transfer oil returns back to the heat furnace to be heated again.

Higher working temperature can be obtained under lower operating pressure;

Better heat stability and accurate adjustment temperature;

Perfect automatic control and safety supervision device;

Heat supply of liquid-phase closed-loop circulation, high utilizing rate of heat with saved fuel;

Selection of top quality elements and materials, long service life of product;

Reasonable technology and advanced control system, products have good operating characteristics, high relability and safety;

Equipments are supplied in batch (on request of customer);

Hot water, steam, hot air as well as other usage can be generated by the heat exchanger.

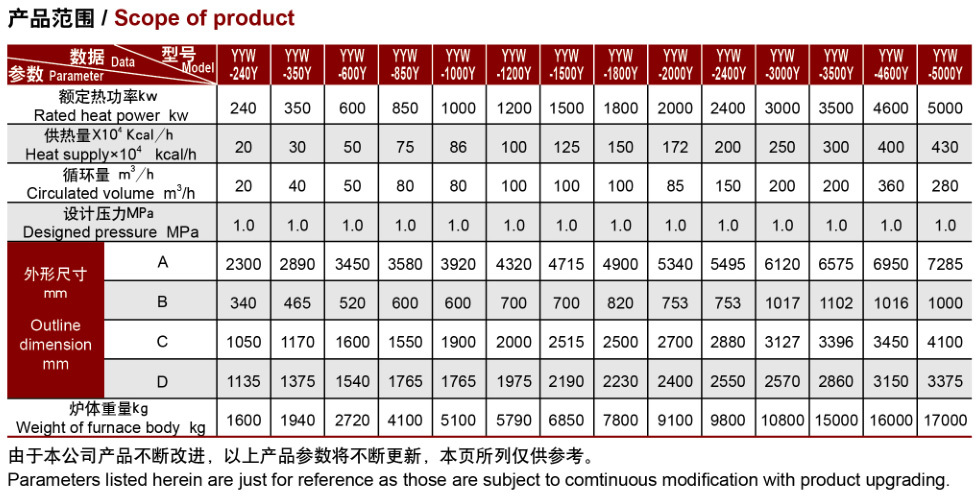

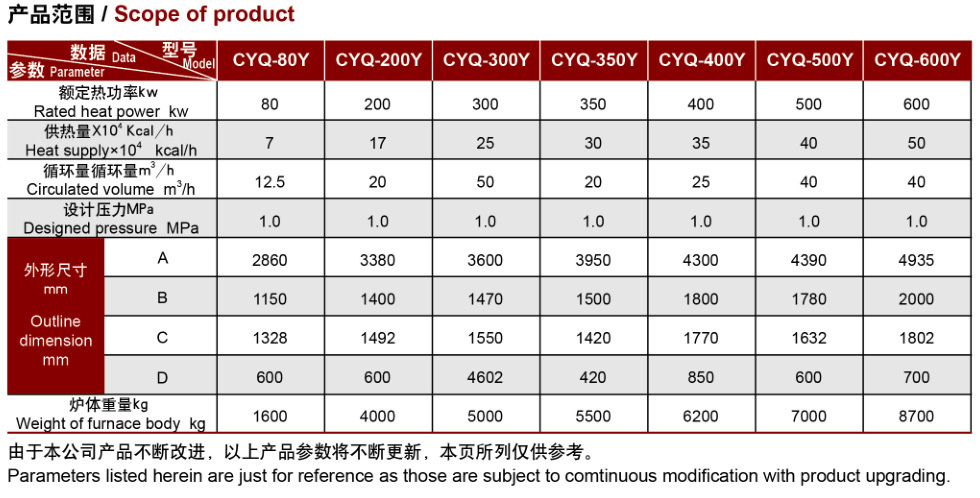

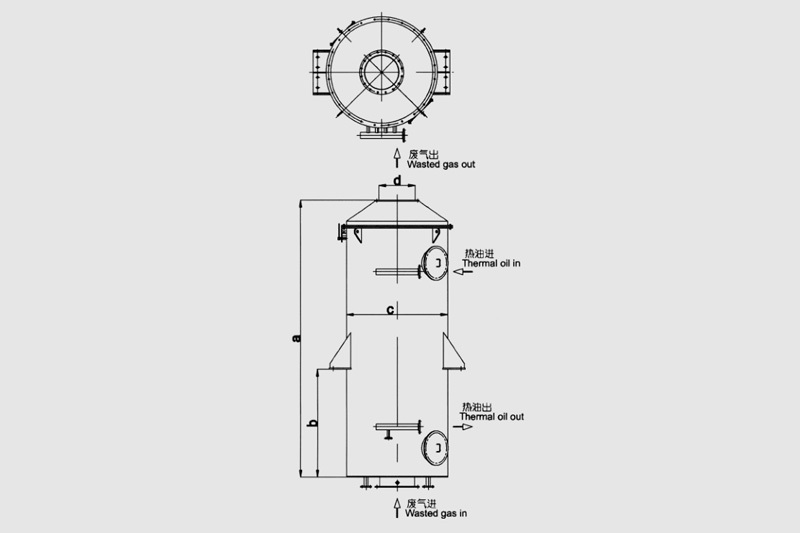

Introduction

The waste gas hot oil furnace takes high temperature tail gas exhausted from the diesel engine set as heat source and takes heattransfer oil as the carrier to transfer heat energy to heat consuming device by means of high temperature hot oil circulation pump with forced liquid-phase closed-loop circulation. After heat exchange heat transfer oil returns back to the heat furnace to be heated again.

Waste heat is eficiently utilized to save energy source;

Higher working temperature can be obtained under lower operating pressure;

Better heat stability and accurate adjustment temperature;

Perfect automatic control and safety supervision device;

Heat supply of liquid-phase closed-loop circulation, high itilizing rate of heat;

Selection of top quality elements and materials, long service life of product;

Reasonable technology and advanced control system, products have good operating characteristics, high relability and safety, simple maintenance of equipment;

Bypass structure for waste gas at the side of the furnace can effectively save occupied space of equipment;

Bypass gate for waste gas can be operated manually or automatically with infinite speed regulation.

Related Products

HI (indirect style), HD (direct style) serial hot-blast furnace is a specialized industrial one produced by pour company. It takes coal, oil (gas) as fuel and mixed smoke and air as the carrier to transfer heat energy to heat consuming equipment by means of forced transfer of the circulation fan.

QXS series molten salt heating furnace is a direct-flow style special industrial furnace which takes coal, oil and gas as fuel and the molten salt as the carrier to transfer heat energy to heat consuming equipments by means of the circulation pump with forced liquid-phase circulation. The molten salt shall be returned to be heated again and the whole system consists of heating furnace, circulation pump and melting system.

The autoclave is a large-scale steam curing equipment and is used for steam curing of sand lime brick, fly ash brick, aerated concrete and building block, high strength cement lamp pole, pipe pile and other cement products. Meanwhile it is also suitable for wood, medicine, chemical, glass and heat preservation industries.

Leaving A Message