Products

Contact Information

Oil-burning (Gas-burning) Organic Heat Carrier Boiler (Vertical/H orizontal)

Product Overview:

Category:

key word: Manufacture of heat carrier boiler | steam boiler

Oil-burning (Gas-burning) Organic Heat Carrier Boiler (Vertical/H orizontal)

Introduction

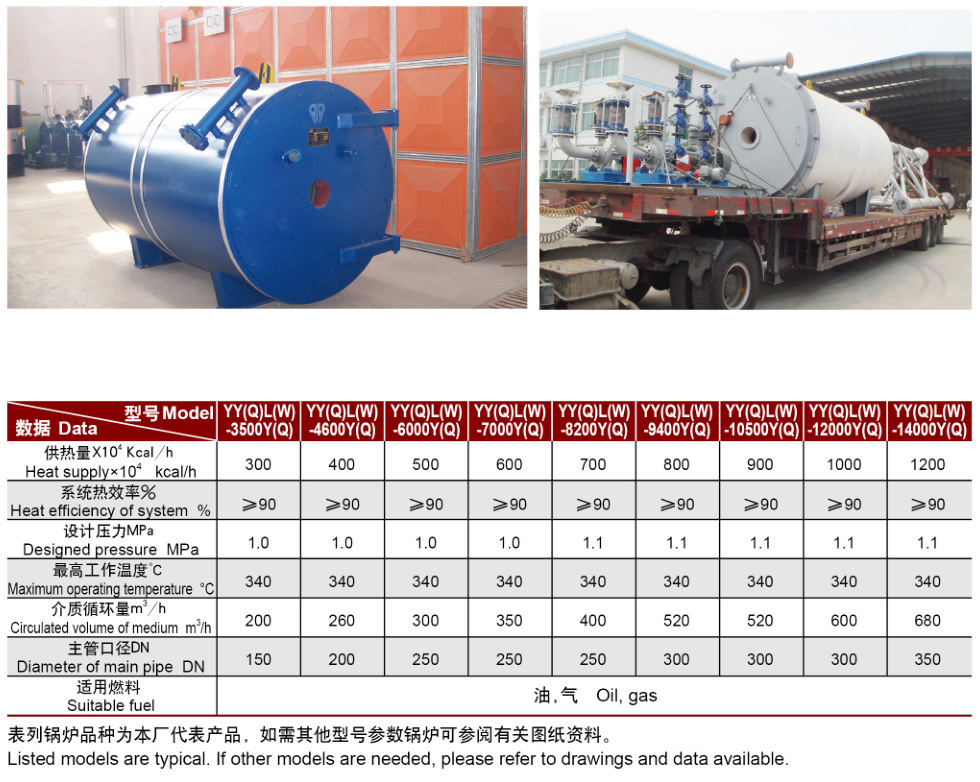

The YYL (YYW) serial organic heat carrier boiler is a package forced-circulation oil-burning (gas-burning) boiler. The serial boiler has compact structure of heating surface which consists of inner, middleand outer (or inner and outer) coils densely arranged. The inner coils are the radiation heating surface while the middle and outer coils and outer surface of the inner coils form the convection heating surface.Fuel is burning and releases heat in the combustion chamber of innercoils and most heat is absorbed by the radiation heating surface. High temperature smoke is heat-exchanged with the convection heating surface and low temperature smoke directly exhausted from thesmoke exit of the boiler to atmosphere via the chimney.

Easy assembling is easy and flexible only by placing the boiler on its foundation.

The heating surface adopted densely arranged coils so it has sufficient arrangement of heating surface to reduce the surface heat load of pipes and make the heat transfer oil safer in use.

The dimensions of the hearth are matched with burning flame and positive pressure burning is adopted to get high heat exchange rate of radiation.

The boiler has compact structure so it can save occupied area of the boiler room.

The air pre-heater is set at the end of the boiler therefore it can rise up efficiency of the boiler.

Related Products

HI (indirect style), HD (direct style) serial hot-blast furnace is a specialized industrial one produced by pour company. It takes coal, oil (gas) as fuel and mixed smoke and air as the carrier to transfer heat energy to heat consuming equipment by means of forced transfer of the circulation fan.

QXS series molten salt heating furnace is a direct-flow style special industrial furnace which takes coal, oil and gas as fuel and the molten salt as the carrier to transfer heat energy to heat consuming equipments by means of the circulation pump with forced liquid-phase circulation. The molten salt shall be returned to be heated again and the whole system consists of heating furnace, circulation pump and melting system.

The autoclave is a large-scale steam curing equipment and is used for steam curing of sand lime brick, fly ash brick, aerated concrete and building block, high strength cement lamp pole, pipe pile and other cement products. Meanwhile it is also suitable for wood, medicine, chemical, glass and heat preservation industries.

Leaving A Message