Products

Contact Information

Steam Generator

Product Overview:

Category:

key word: Manufacture of heat carrier boiler | steam boiler

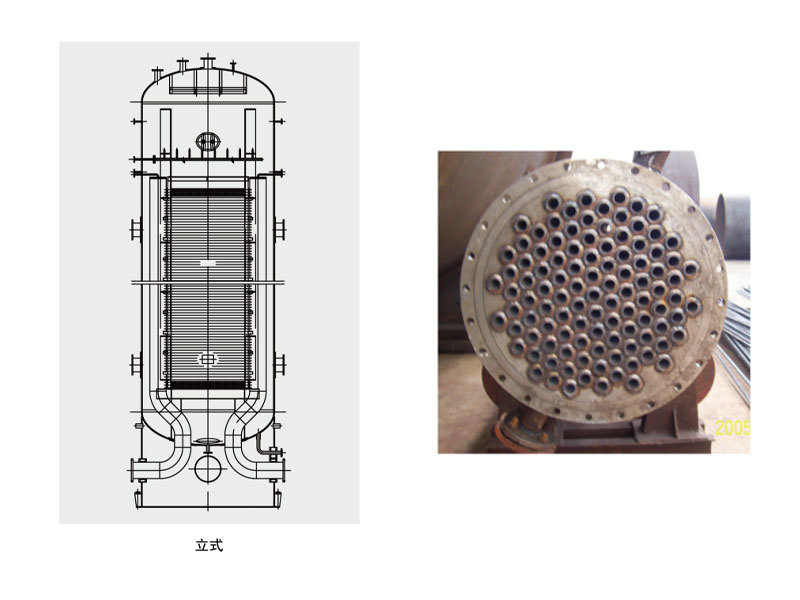

Steam Generator

Introduction

The steam generator is an indirect flame heating device. Some of high temperature heat transfer oil generated from the organic heat carrier boiler comes into the steam generator, in which high temperature heat transfer oil makes heat exchange with water to generate steam, which can be provided continuously or intermittently according to actual working conditions. Compared with the steam boiler, it has characteristics of investment reduction, energy saving, simple assembling, operation and maintenance etc.

Main sizes of heat exchange area of the steam generator are as follows: 15m2, 20m2, 30m2, 40m2, 60m2, 78m2, 90m2, 100m2,120m2, 180m2, 180m2, 245m2, 300m2, 360m2, 400m2, 450m2, 500m2, 550m2 and 600m2 or it can be additinaly designed as per requirement of customer.

The steam generator can be used together with the organic heat carrier boiler thus it can not only provide the customer high temperature heat carrier but also provide required steam to widely meet requirement of production and life.

Main Advantages:

1. Adopt the serpentine tubes which can be freely expanded;

2. Vertical arrangement with less occupied area;

3. Adopt framework support structure, each serpentine tube has independent support and can be freely expanded;

4. Steam has high space and two-stage steam/water separation is adopted therefore quality of steam is high.

The maximum capacity is 30t/h and it has two series products: vertical and horizontal.

next

next

Related Products

HI (indirect style), HD (direct style) serial hot-blast furnace is a specialized industrial one produced by pour company. It takes coal, oil (gas) as fuel and mixed smoke and air as the carrier to transfer heat energy to heat consuming equipment by means of forced transfer of the circulation fan.

QXS series molten salt heating furnace is a direct-flow style special industrial furnace which takes coal, oil and gas as fuel and the molten salt as the carrier to transfer heat energy to heat consuming equipments by means of the circulation pump with forced liquid-phase circulation. The molten salt shall be returned to be heated again and the whole system consists of heating furnace, circulation pump and melting system.

The autoclave is a large-scale steam curing equipment and is used for steam curing of sand lime brick, fly ash brick, aerated concrete and building block, high strength cement lamp pole, pipe pile and other cement products. Meanwhile it is also suitable for wood, medicine, chemical, glass and heat preservation industries.

Leaving A Message